Email format error

Email cannot be empty

Email already exists

6-20 characters(letters plus numbers only)

The password is inconsistent

Email format error

Email cannot be empty

Email does not exist

6-20 characters(letters plus numbers only)

The password is inconsistent

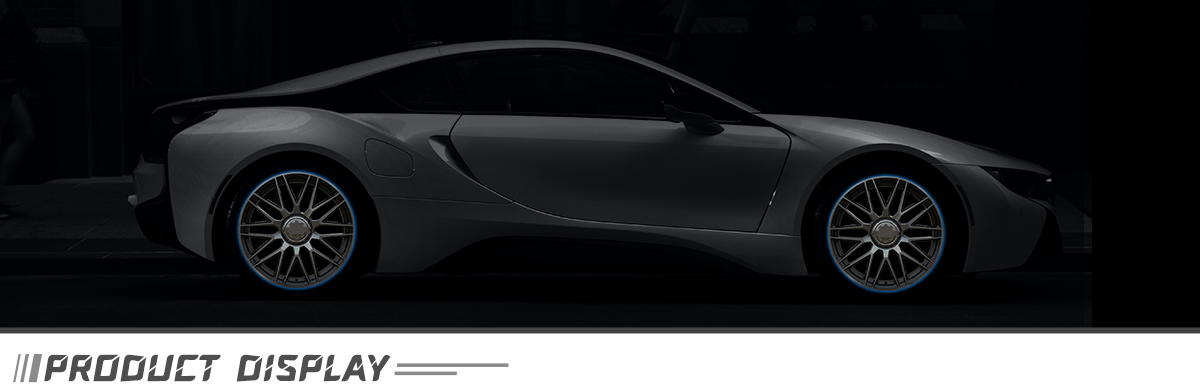

2023 NEW Mercedes glc alloy wheels

Our wheels of the vehicle create a smooth and comfortable ride due to their high roundness, which provides an accurate motion. Furthermore, energy absorption reduces vibrations and noise from the road surface. This results in a quiet, peaceful, and comfortable journey for all passengers.

FITMENT SIZE ET PCD CB

MERCEDES-BENZ 1985 35-42 5*112 66.6

MERCEDES-BENZ 1995 35-45 5*112 66.6

In order to meet the demands of consumers, car manufacturers have been working hard to develop superior automotive materials. The most important and hot-selling material for aircraft and cars has been aluminum alloy wheels. Through the application of aluminum alloy wheels, drivers can drive vehicles more smoothly on a variety of roads and achieve better fuel mileage. The main advantages of aluminum wheels are lightweight, toughness and high performance. In addition, they are cheap, durable and easy to maintain. They can last more than 20 years if they are well maintained. Therefore, many car owners use them as original car wheels instead of steel wheels. Used by professional car racers, many world-famous teams are also available in their best racing cars.

1.Features of 2023 NEW Mercedes glc alloy wheels

The unique design of the wheels also enhances aerodynamics and maximizes fuel efficiency.

2.Advantages

Our wheels of the vehicle create a smooth and comfortable ride due to their high roundness, which provides an accurate motion. Furthermore, energy absorption reduces vibrations and noise from the road surface. This results in a quiet, peaceful, and comfortable journey for all passengers.

3.Our Service

We can provide a one-to-one product customization service.

We can help customers go online and recommend hot-selling wheel products according to the customer market.

We can provide door-to-door sea, land and air freight services.

What material are the wheels of the car made of? There are mainly four common materials: steel wheels, aluminum alloy wheels, magnesium alloy wheels, and carbon fiber composite wheels.

Steel hub

Steel wheels are made of steel and are also a relatively common material. The advantages of steel wheels are low cost and low manufacturing cost, but you get what you pay for. Its heat dissipation capacity is very poor, and it is easy to rust on rainy days.

Materials involved: carbon steel, ductile iron.

Aluminum alloy wheels

Aluminum alloy wheels are mostly made of aluminum as the basic material, with appropriate addition of manganese, magnesium, chromium, titanium and other metal elements. Compared with iron hubs, the mass is small. Aluminum alloy rims should be light and small steel rims, which can make a great contribution to the fuel economy of the vehicle. Moreover, the heat dissipation performance is good, which can improve the tire life. Some aluminum alloy rims can rely on their own styling functions to direct the airflow to the brakes during rotation to improve heat dissipation.

The roundness is high, which can improve the motion accuracy of the wheels, and is suitable for high-speed driving. It has good energy absorption, can absorb vibration and noise from the road surface, and improve the ride comfort of the vehicle. High rigidity, which can effectively reduce the damage to the rim shape caused by road impact. There are few modeling restrictions, and various rims can be designed according to requirements. However, its biggest disadvantage is that the manufacturing process is complicated and the cost is high.

Materials involved: aluminum alloy A356.20.

Magnesium alloy wheels

Magnesium alloy is a metal material that has received extensive attention in the fields of automobiles and electronic products in recent years, and it is the lightest structural material currently used. Due to its light weight (specific gravity of 1.74 g/cm3) and good mechanical properties, it has begun to be used in batches in the field of vehicles and electronics.

Magnesium alloy is an alloy composed of magnesium as the matrix and other elements added. Its characteristics are: low density (about 1.8g/cm3 magnesium alloy), high specific strength, large specific elastic modulus, good heat dissipation, good shock absorption, higher impact load capacity than aluminum alloy, and corrosion resistance to organic substances and alkalis. it is good. The main alloying elements are aluminum, zinc, manganese, cerium, thorium and a small amount of zirconium or cadmium.

At present, the most widely used is magnesium-aluminum alloy, followed by magnesium-manganese alloy and magnesium-zinc-zirconium alloy. Mainly used in aviation, aerospace, transportation, chemical, rocket and other industrial sectors. It is the lightest metal in practical use, and the specific gravity of magnesium is about 2/3 of that of aluminum and 1/4 of that of iron. It is the lightest metal among practical metals, with high strength and high rigidity.

Materials involved: magnesium alloy.

Carbon fiber composite wheels

The carbon fiber composite wheel hub is made of composite material, so its cost is relatively high. But on the other hand, it has better anti-noise performance and is easy to repair even if it is damaged.

Of course, the wheels of the car are not only these four materials, there are others. Different materials have different functions and advantages. When choosing, you should choose suitable materials according to your actual situation.